Choosing the right needle for the job and using it correctly is as important as stabilizing and hooping your embroidery. If you are having problems with thread breaks, skipped and uneven thread the first thing to do is to change your needle.

There are many types of needles suitable for machine embroidery and it is best to have a selection on hand and choose the right one for the job. Needles blunt easily with use (especially with stabilizers) and it is important to change them frequently (about every 100,000 stitches). A sharp needle will penetrate the fabric cleanly and will result in a well-stitched design. A blunt needle can catch on the fabric or the embroidery and ruin your work.

The larger the needle number - the larger (and stronger) the needle. Sizes range from 60/8 to 110/18. Always choose the smallest possible needle for the design, fabric and thread you are using. The thread should easily pass through the eye of the needle - if it doesn't, use a larger size needle. All needles produce holes in the fabric as you sew and using an unnecessarily large needle will weaken the fabric around and underneath the design.

If you are having problems with the thread breaking or shredding, the first thing to do is to change your needle – either to a larger size or to a brand new needle.

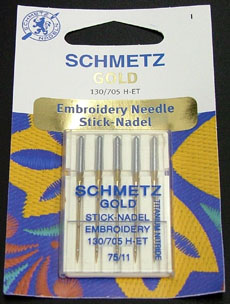

* Embroidery. This is the most common and frequently used needle for machine embroidery on everyday material. It is designed for rayon, polyester and fine cotton (50wt) thread. It has a slightly larger eye and the eye is smooth so it reduces the chance of the thread breaking or shredding as it passes through. Start with a 75/11 and, if the thread breaks or shreds, go up to a 90/14. * Gold embroidery needle. These needles are coated with titanium which resists adhesives and penetrates course and densely woven material better. The needle has a slightly rounded point and a large eye. They last way longer than normal embroidery needles – up to twice as long. They are available in 75/11 and 90/14

* Metallic. These needles are designed for use with metallic thread. They have a large, elongated eye and a grooved shaft so the thread moves through the needle and fabric better. This reduces the heat and friction and results in less thread breaks. They come in the two sizes - 80/12 and 90/14. Because of the abrasion the eye of these needles receive from metallic thread, they have to be changed more frequently than ordinary needles – around every 50,000 stitches. If your metallic thread is fraying then change the needle.

* Jeans (also called denim needles). They have a strong shaft and a very sharp point. The eye is bigger than usual so they are suited for embroidering on heavier materials such as heavy fabric, canvas, tin foil and leather. These come in many sizes - 70, 80, 90, 100,110 and in assorted packs. * Microtex (also called sharps). These are used to sew on tightly woven fabric. These needles are very sharp and cut through the fabric as you sew: resulting in a smooth edge to your embroidery. They come in various sizes including the 60/8, which is the smallest needle available.

* Quilting. These needles are designed for machine quilting as they are sharp and can penetrate through many layers. Their eye is not as smooth as embroidery needles so they are not the best choice for machine embroidery. They come in two sizes – 75/11 and 90/14.

* Twin embroidery. This is a specialist needle mainly used in heirloom embroidery. They come in 2.0 and 3.0 and the size relates to the distance between the two needles. Follow your machine’s directions on how to thread them.